Plastic rubber industry

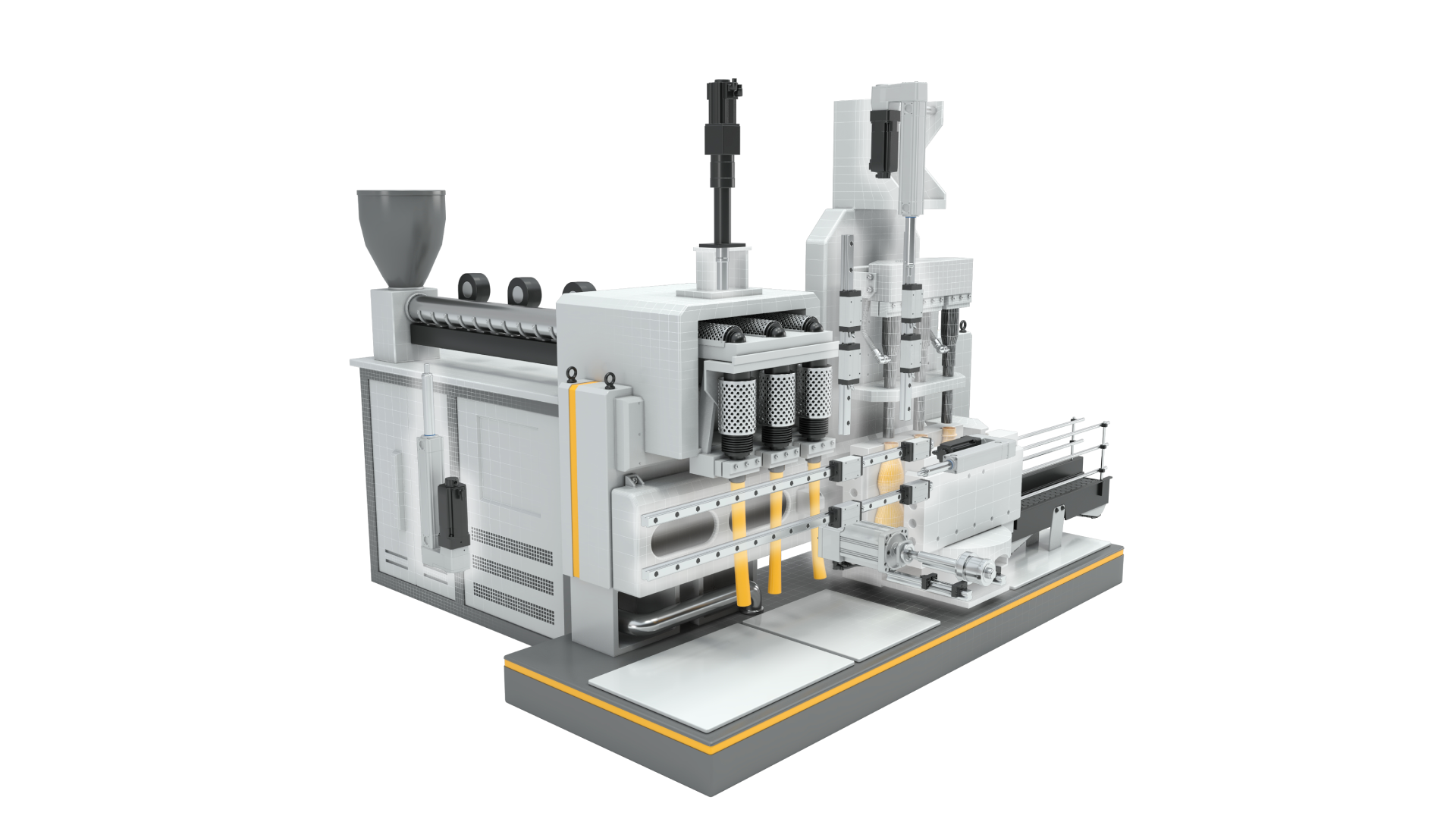

Manufacturers of plastic injection moulding systems use various hybrid solutions or all-electric systems with mechatronic components in addition to conventional hydraulic systems to increase their production capacity.

Electromechanical actuators can replace hydraulic drives for the four main axes: Injection, mould closing, part ejection and metering.

Electromechanics offer a number of benefits such as longer uptime, higher accuracy, oil-free processes and longer life, which in turn reduces the total cost of ownership for the end user.

Ewellix supports the plastic rubber industry sector in many areas with a wide range of products and solutions, including linear actuators, linear guides and roller screws for plastic rubber industry.

Related applications

Plastic injection moulding

Plastic injection moulding faces ever increasing challenges for more sustainable plastic parts injec...

Read more

Blow moulding

Plastic blow moulding faces ever increasing challenges for the production of more sustainable plasti...

Read more

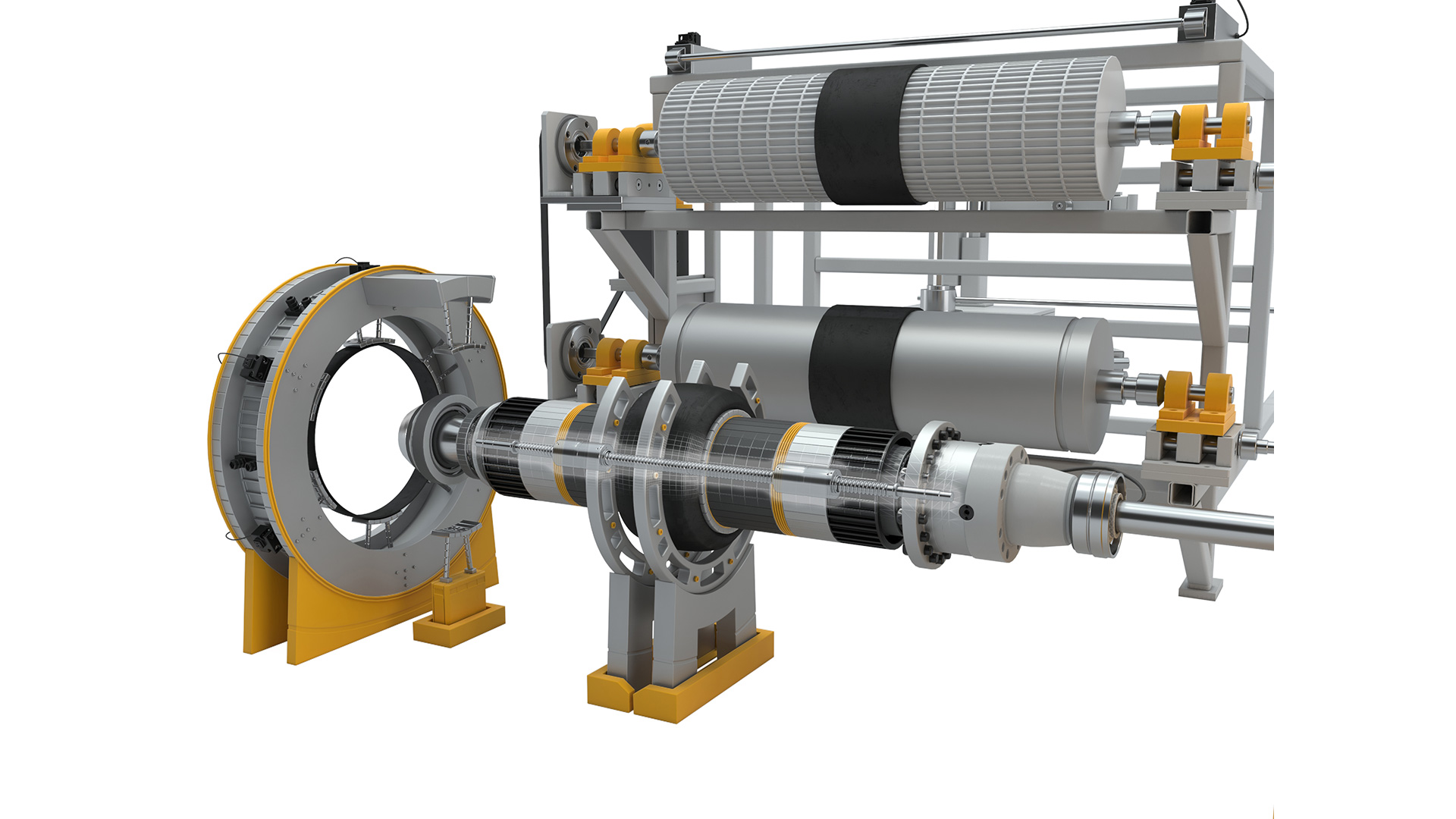

Tyre manufacturing

Tyre building machines are a key element of tyre manufacturing that assembles all components such as...

Read more

Ultrasonic plastic welding

Ultrasonic welding is one of the most widely used processes for bonding polymers, valued for its spe...

Read moreNeed more

information?

Ask our experts.