Ewellix's extensive experience and knowledge of electromechanical solutions can satisfy the most demanding requirements. With the widest range on the market of linear actuators, control units and operating devices, Ewellix is the preferred partner to match your unique application needs.

Electric linear actuators create stable, accurate back and forth movement. These devices have an endless range of applications. If the process involves pushing, pulling, lifting or sliding, a linear actuator can be a key part of the solution.

Ewellix supplies a wide range of industrial linear actuators and their associated control units and accessories. We specialise in compact, heavy duty linear actuator, high-quality devices, suitable for many different industry applications (including linear lift actuator) and high performance linear actuator. A variety of stroke ranges are available, as well as linear actuators that can handle medium and high loads. An example is the linear screw actuator.

Our range of electric linear actuators

Matrix series linear actuators

- Max load up to 8 kN

- Max speed up to 13 mm/s

- Voltage: 12 or 24 V DC, 120 or 230 V AC

- Silent operation

CAJA 35C

- Max load up to 3,5 kN

- Max speed up to 7,5 mm/s

- Voltage: 24 V DC

- Integrated Quick Release function

Ecomag

- Max load up to 6 kN

- Max speed up to 9 mm/s

- Voltage: 24 V DC

- Housing fits a SEM control unit

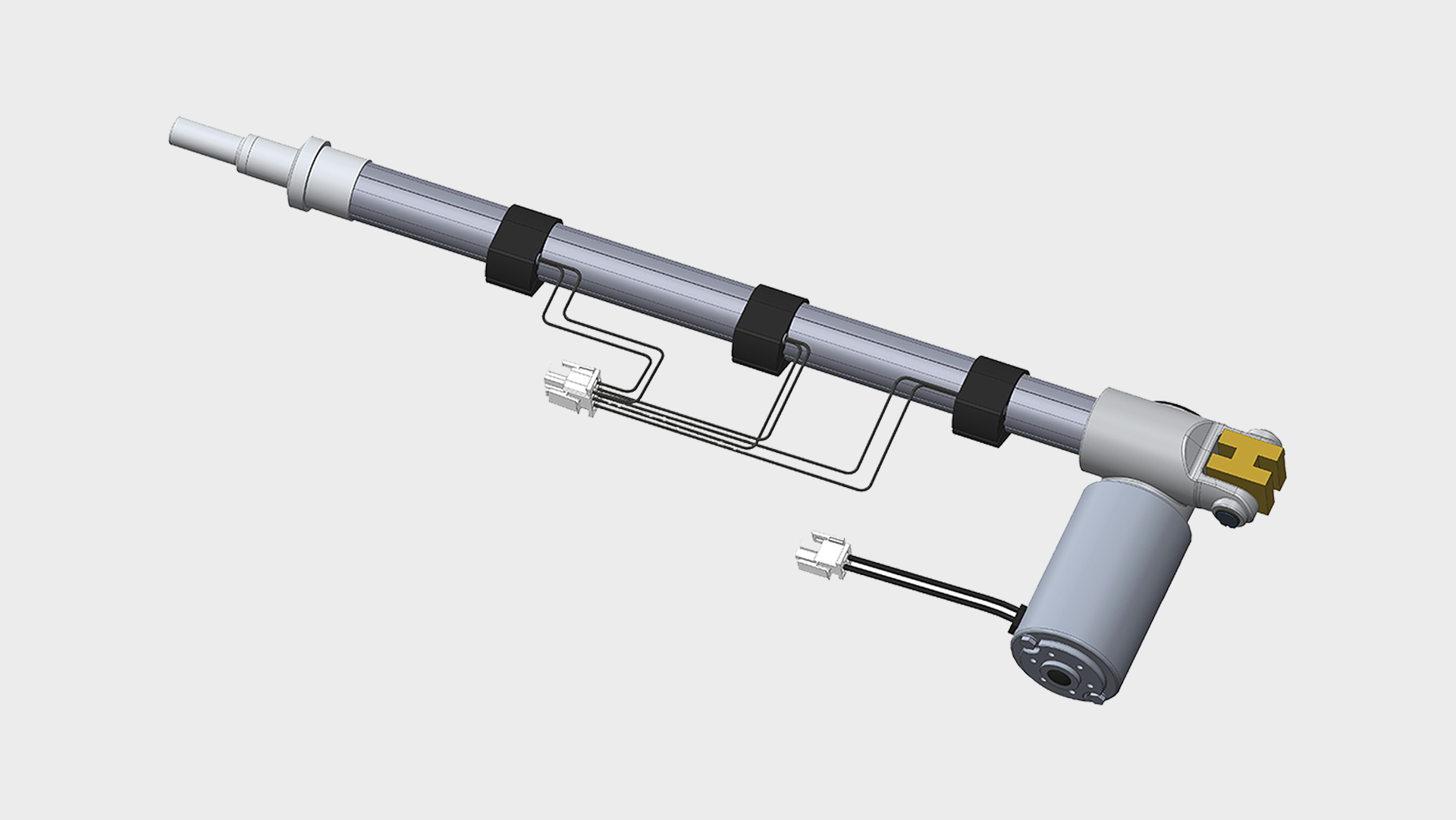

CAHB series linear actuators

- Max load up to 10 kN

- Max speed up to 60 mm/s

- Voltage: 12, 24, 48 V DC. 115 or 230 V AC

- Up to IP69K/66M, wide temperature range

CAT, CAR & CAP series linear actuators

- Max load up to 4 kN

- Max speed up to 193 mm/s

- Voltage: 12, 24 V DC, 120, 230, 400 V AC linear actuator

- Modular range for easy integration

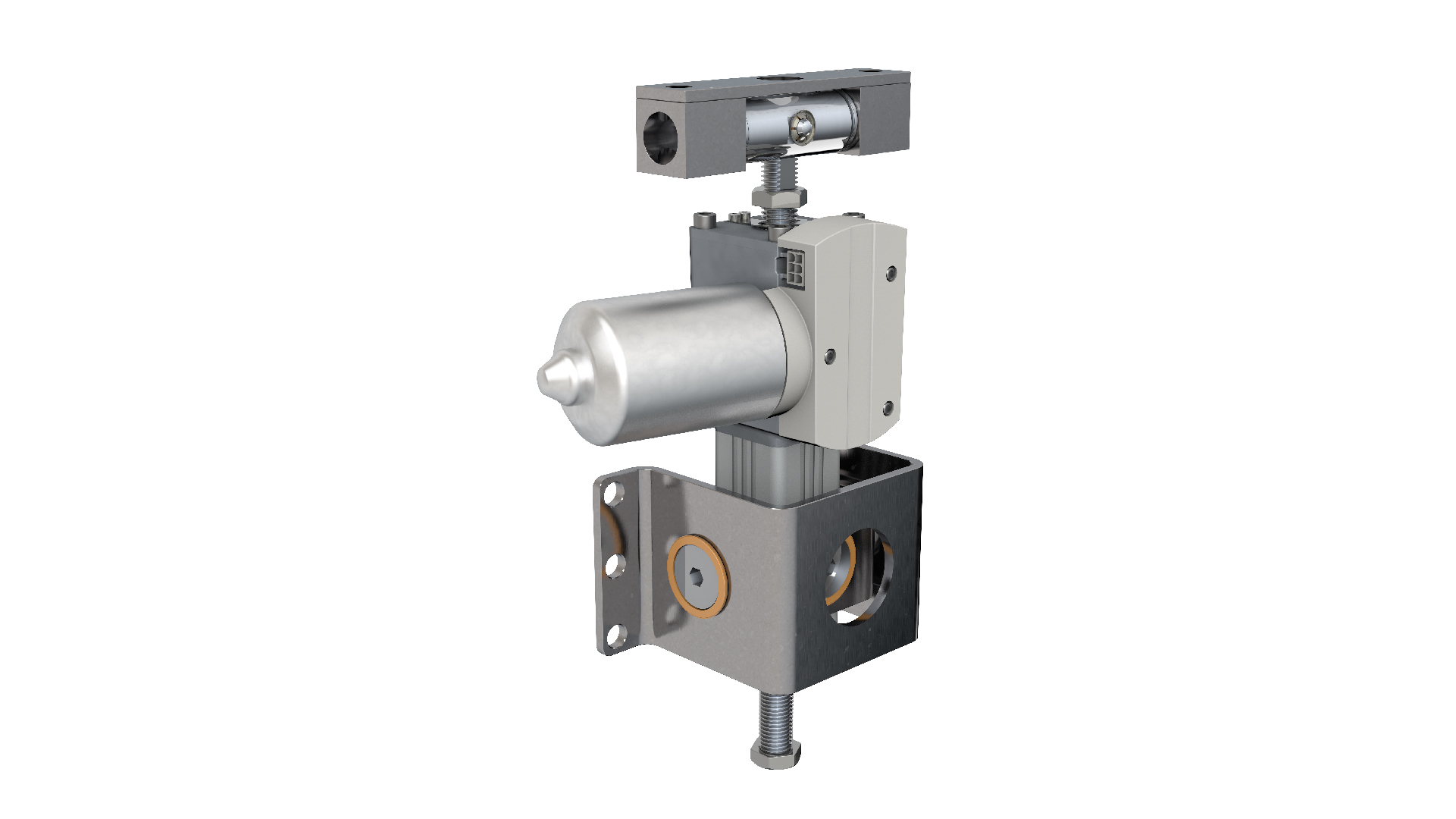

CAMT - Play-free tilting actuator

- Max load up to 6 kN

- Max speed up to 5 mm/s

- Voltage: 24 V DC

- Play free motion

CAFL - Floor lock actuator

- Max load up to 1,7 kN

- Max speed up to 12 mm/s

- Voltage: 24 V DC

- Static load up to 7,5 kN

CAWD - Wind deflector actuators

- Max load up to 0,5 kN

- Max speed up to 16 mm/s

- Manual and electrical 12 V DC versions

- IP 67/69K, wide temperature range

Control units for linear actuators

- Fitted with a 110 or 230 V AC or 24 V DC power supply

- 2, 3, 5 or 6 output channels 24 V DC, max. 18A, 30A for DC input

- Up to 3 control gear connections

- Rechargeable battery or removable rechargeable battery and wall charging station optional

Operating switches

- Up to 10 console switches

- DIN7, FCC or HD15 connectors

- Up to IP67

- Display for stored functions available as an option

Video

Low duty actuators

Are you looking for a customised linear motion solution?

Find out how our customisation capabilities can meet your needs

Read more

Frequently asked questions

Need more

information?

Ask our experts.