Linear guides provide a precise guiding function for positioning loads in combination with linear motion driving elements, such as actuators or ball screws. As linear guide rail manufacturers, our linear range includes precision rail guides, various profile rail guides, linear guide rail systems, heavy duty linear guide rails, linear plain bearings and linear ball bearings, as well as units with precision shafts. From a few micron of stroke up to several meters of movement, almost any precise motion application in industrial or office environments is possible. The high product standardisation provides high-quality components even for applications with the lowest friction or noise emission request.

Linear guides product range

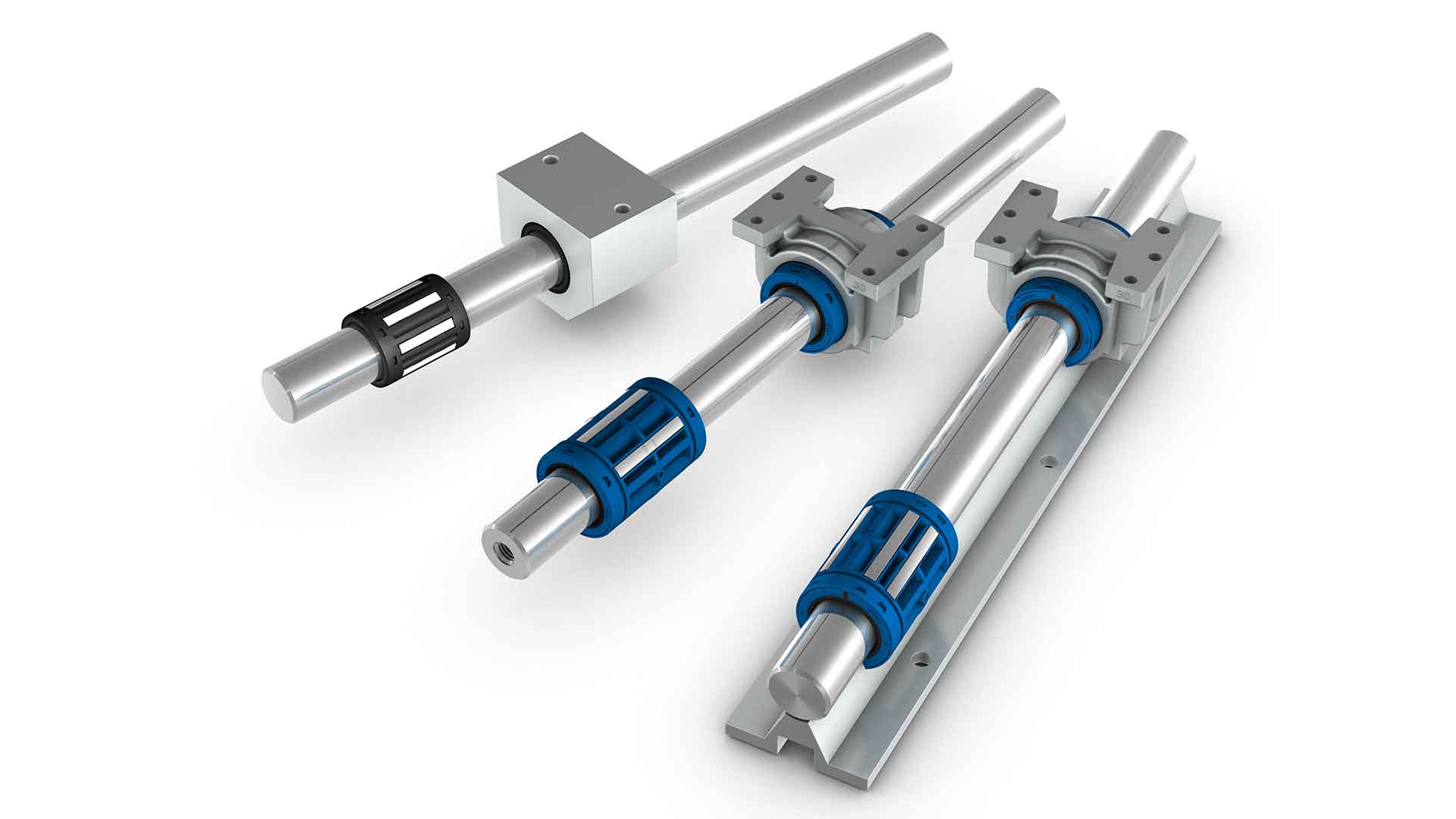

Linear bearings, units and shafts

- Wide assortment from 3 mm to 80 mm

- Most effective sealing on a round shaft

- Insensitive against misalignment

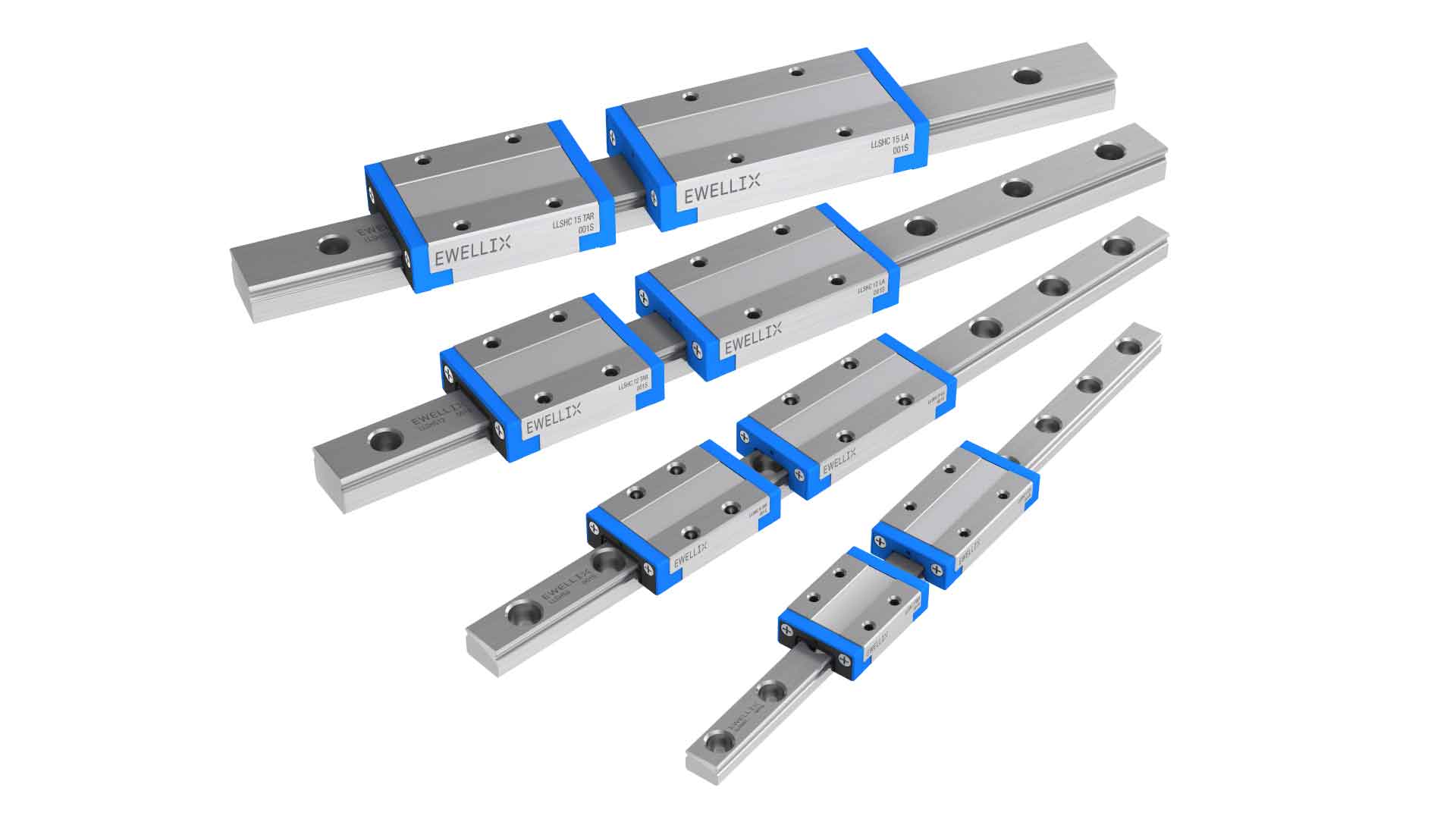

Miniature profile rail guides

- Zero Rail Concept from size 7 to 15

- Most safe unique ball retention system

- Low noise and smooth running

Ball profile rail guides

- Range from size 15 to 45

- Most used linear guides

- Standard with side and inner seals

Precision rail guides

- Wide range and easy customizations

- Highest possible precision

- Lowest friction at highest rigidity

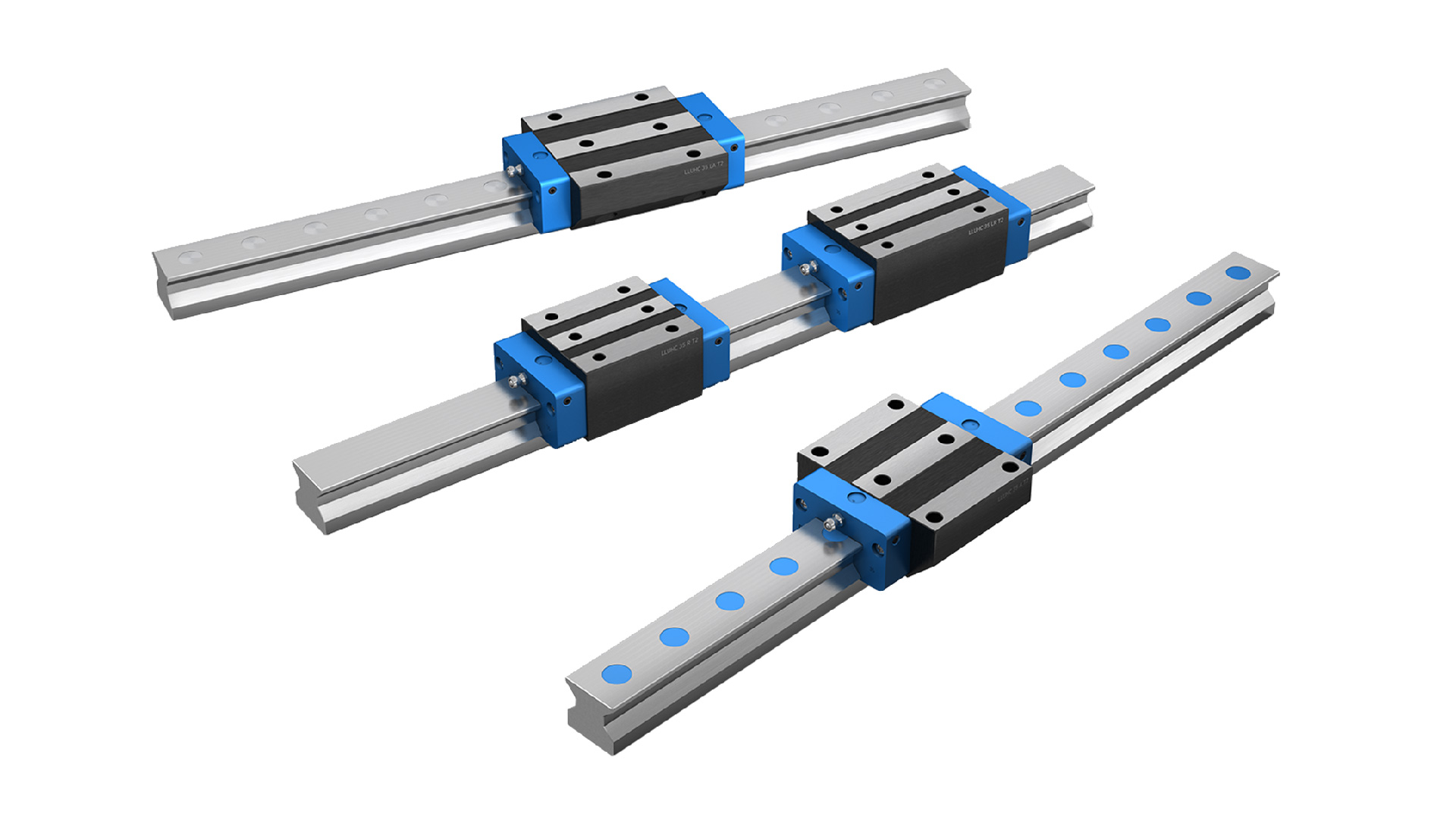

Roller profile rail guides

- Wide range from size 25 to 65

- Highest load carrying capacity

- Highest profile rail accuracy

Frequently asked questions

A linear guide is a precise, mechanical device that ensures smooth and accurate linear motion between two parts. Thanks to good wear resistance it helps to realize long lasting processes and constant machine performance in various applications.

The main features of a linear guide are low friction, high accuracy, and repeatability in motion. Due to the different types and product ranges of linear guides there is a large flexibility when designing mechanical systems.

A linear guide is used in a variety of different applications. It can move a robot to extend its reach, handle boxeserz in a warehouse, precisely move a grinding wheel, pick and place probes in a laboratory or adjust the bed in an ambulance. Always providing precise, smooth and safe linear movement of any kind of loads. For fully automated solutions linear guides are combined with screws, belts or actuators that generate the needed driving force.

Need more

information?

Ask our experts.