ACS

ACS

The plastic wheel is best for cross roller assemblies with long strokes and medium accelerations. The cage motion is controlled by the plastic wheel.

The plastic wheel is best for cross roller assemblies with long strokes and medium accelerations. The cage motion is controlled by the plastic wheel.

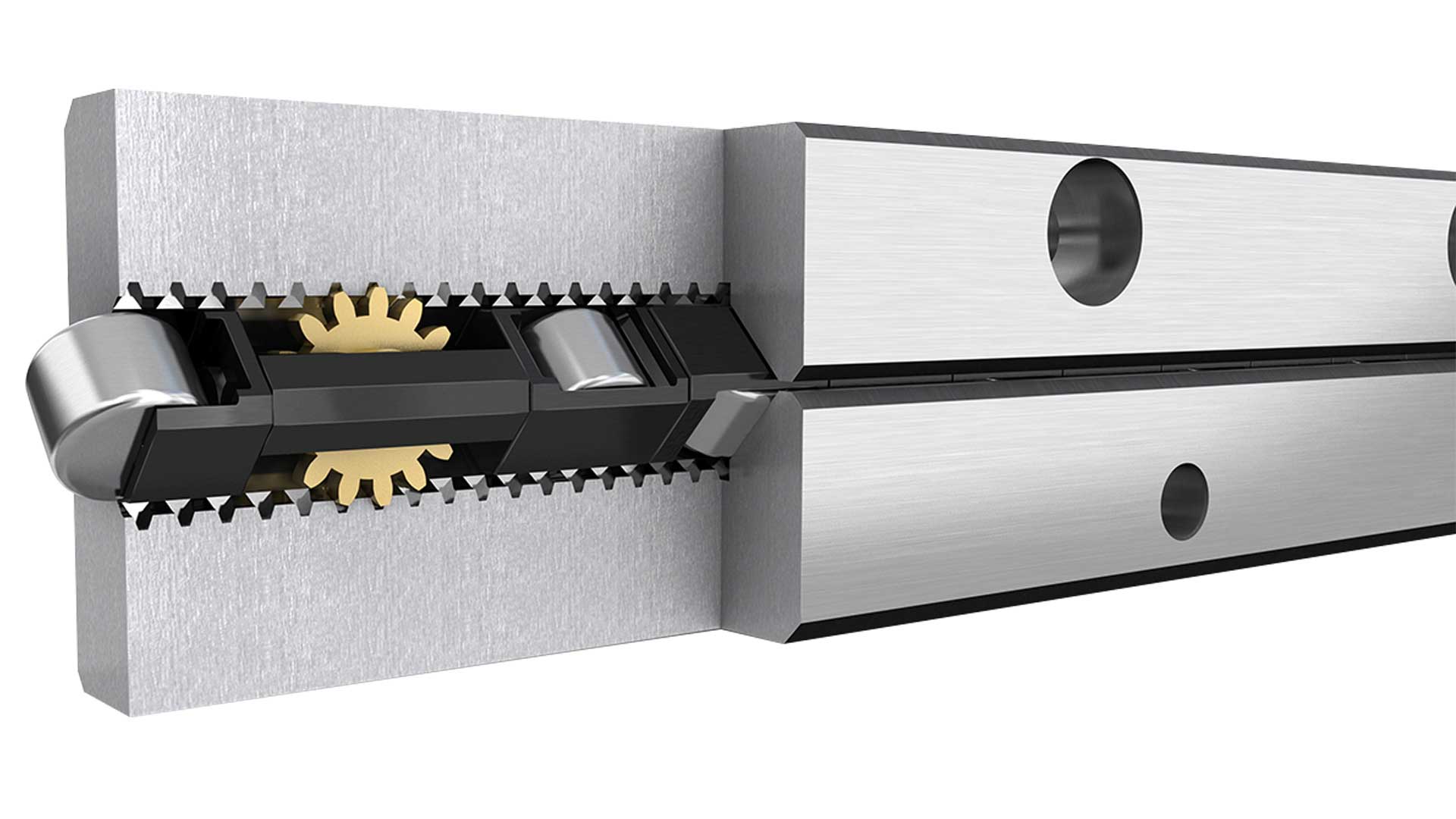

The involute-toothed control gear made of brass, and a rack directly machined into the rail is especially suitable for high accelerations. The maximum toothed rail length is limited to 400 mm.

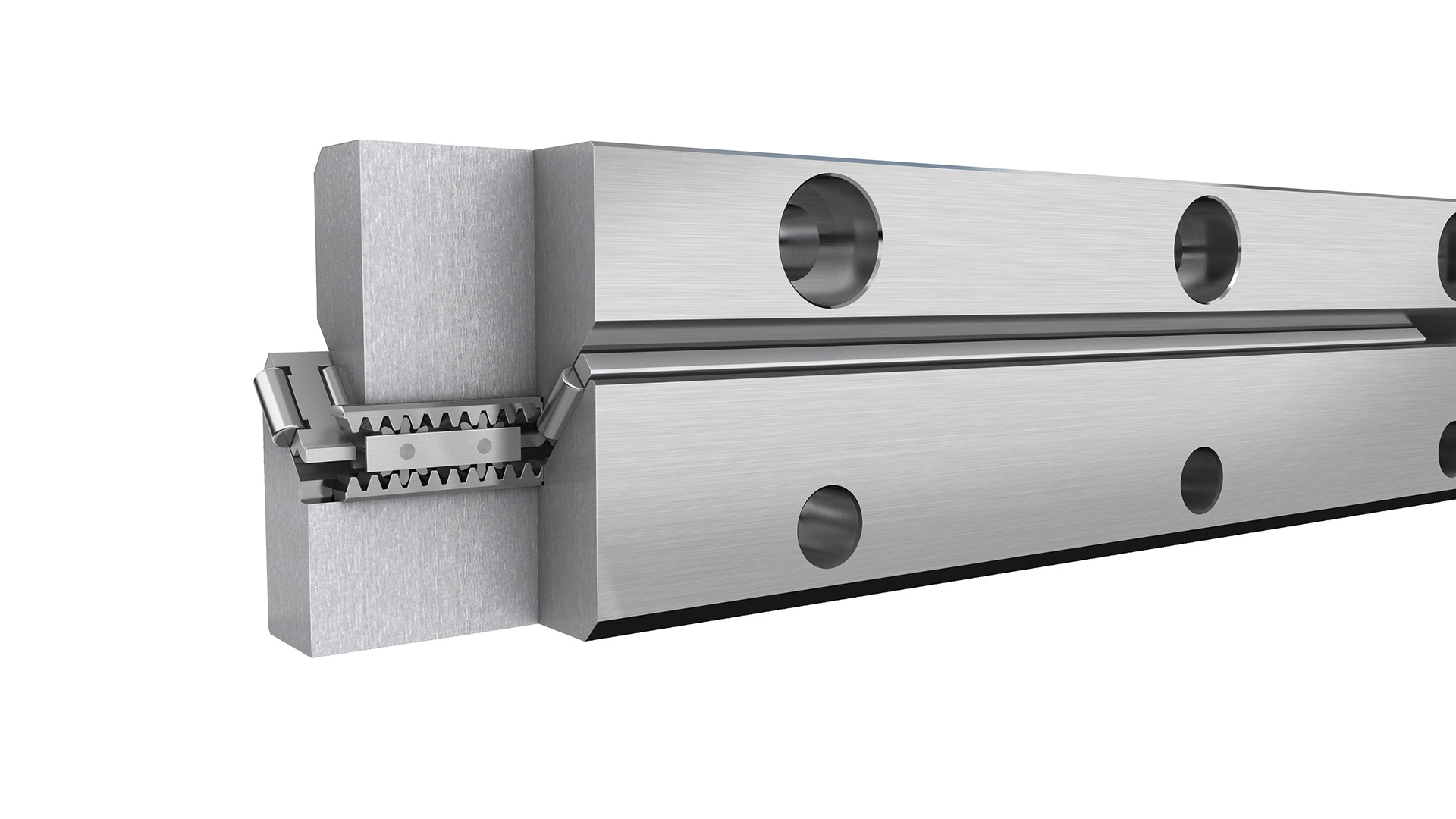

Both rails are equipped with steel gear racks. The cage carries two steel control gears that help maintain the correct position of the cage.