LIFTKIT

Benefits

- Extend cobot operating range to increase productivity and save costs

- Plug-and-play solution compatible with virtually any robot brand (according LIFTKIT’s specifications payload, dynamic & static moment)

- No hardware/software upgrades required

- Direct positioning access within the robot control environment (where available)

- Vibration-free movement

- High positioning precision

- Compatible with several palletising software such as Pally

- Compatible with VISUAL COMPONENT software

Features

- Approved positioning axes for Universal Robots, Omron, Techman, FANUC collaborative robots

- Directly recognised by Pally software as lifting solution

- Ready-to-use complete system

- Robust column design for industrial use

- Silent operation

- High stiffness

Ewellix LIFTKIT is a ready-to-install system and includes a lifting column with a robot mounting interface, a controller and a software plug-in for compatible robots so that movements can be programmed directly via the robot controller.

In the LIFTKIT-0S version, the column can be controlled via a standard Ethernet TCP/IP interface. With a set of simple commands, it is possible to connect the LIFTKIT to virtually any type of robot and create a dedicated programme to perform the lifting function.

Product overview

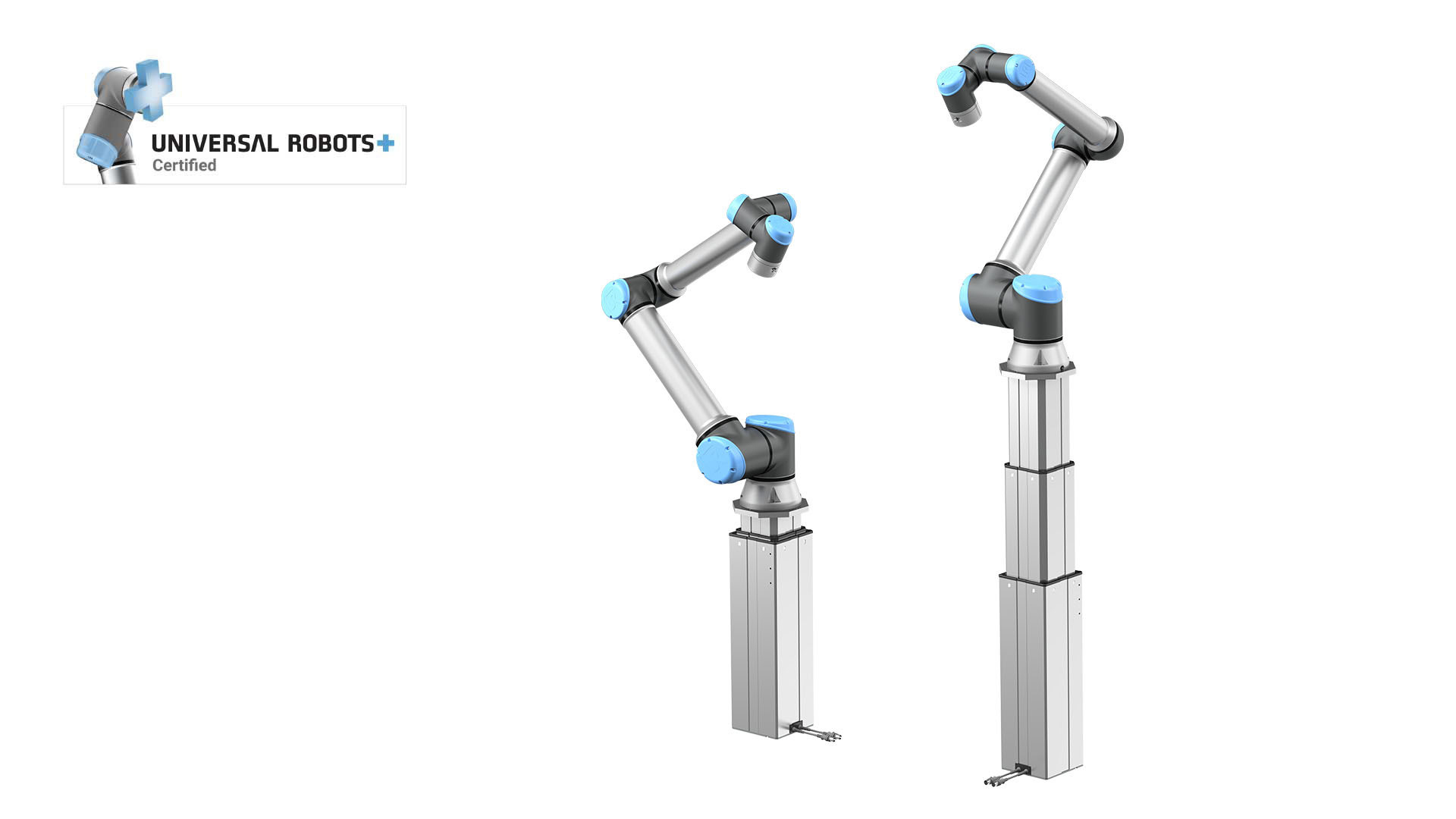

LIFTKIT-UR

- Load up to 1,5 kN

- Speed up to 80 mm/s

- Stroke up to 1 400 mm

- Plug and play with Universal Robots

LIFTKIT-OM

- Load up to 1,5 kN

- Speed up to 80 mm/s

- Stroke up to 1 400 mm

- Plug and play with Omron TM

LIFTKIT-TM

- Load up to 1,5 kN

- Speed up to 80 mm/s

- Stroke up to 1 400 mm

- Plug and play with Techman TM

LIFTKIT-0S

- Load up to 1,5 kN

- Speed up to 80 mm/s

- Stroke up to 1 400 mm

- Compatible with any robot

LIFTKIT-FA

- Load up to 1,5 kN

- Speed up to 80 mm/s

- Stroke up to 1 400 mm

- Plug and play with FANUC cobot

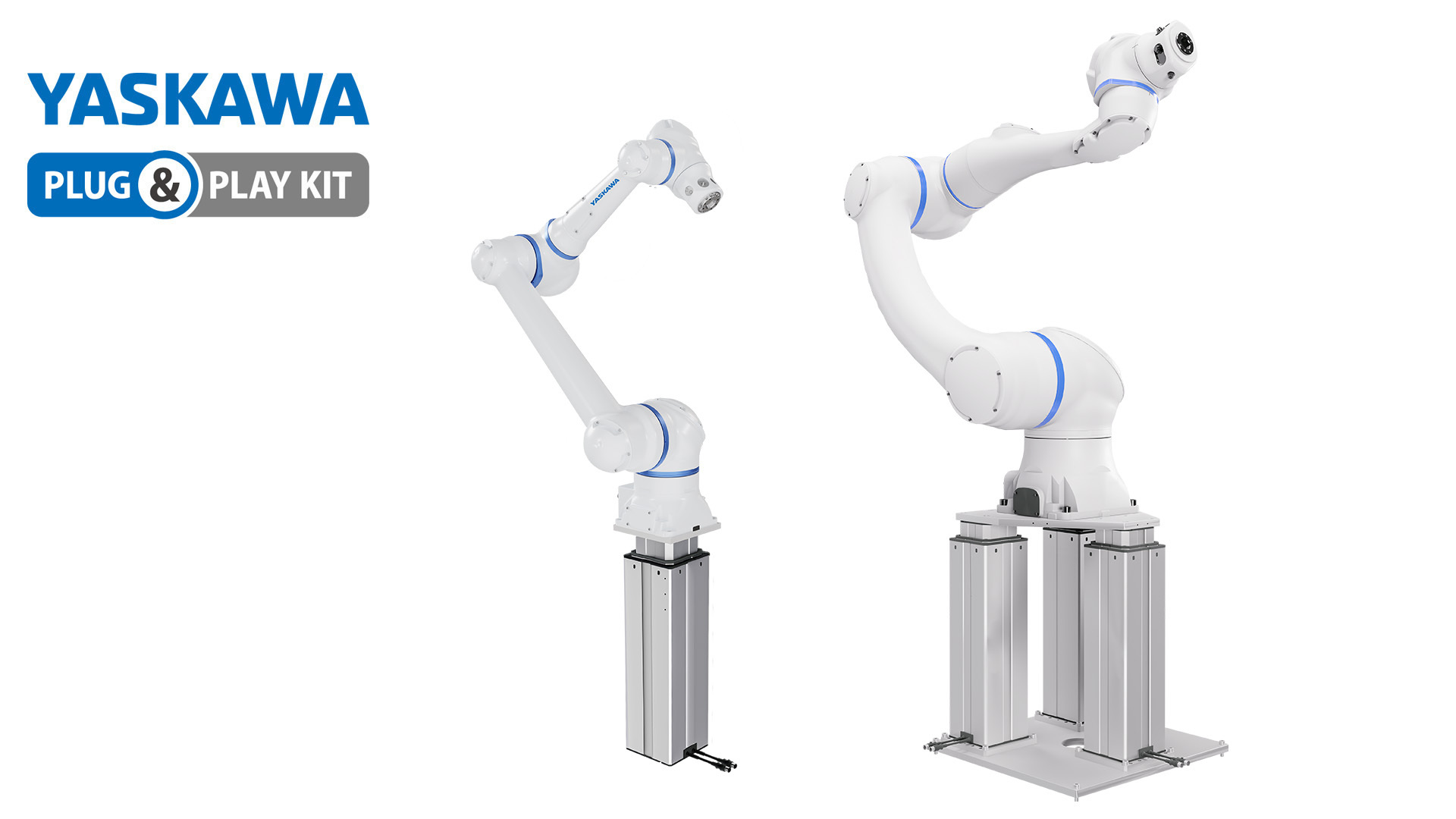

LIFTKIT-YA

- Load up to 1,5 kN

- Speed up to 80 mm/s

- Stroke up to 1 400 mm

- Plug and play with YASKAWA cobot

Videos

LIFTKIT - Discover how to increase the productivity of your robot

Liftkit and slidekit - extend your possibilities

Need more

information?

Ask our experts.