Why we switched from fluid power actuators to electric

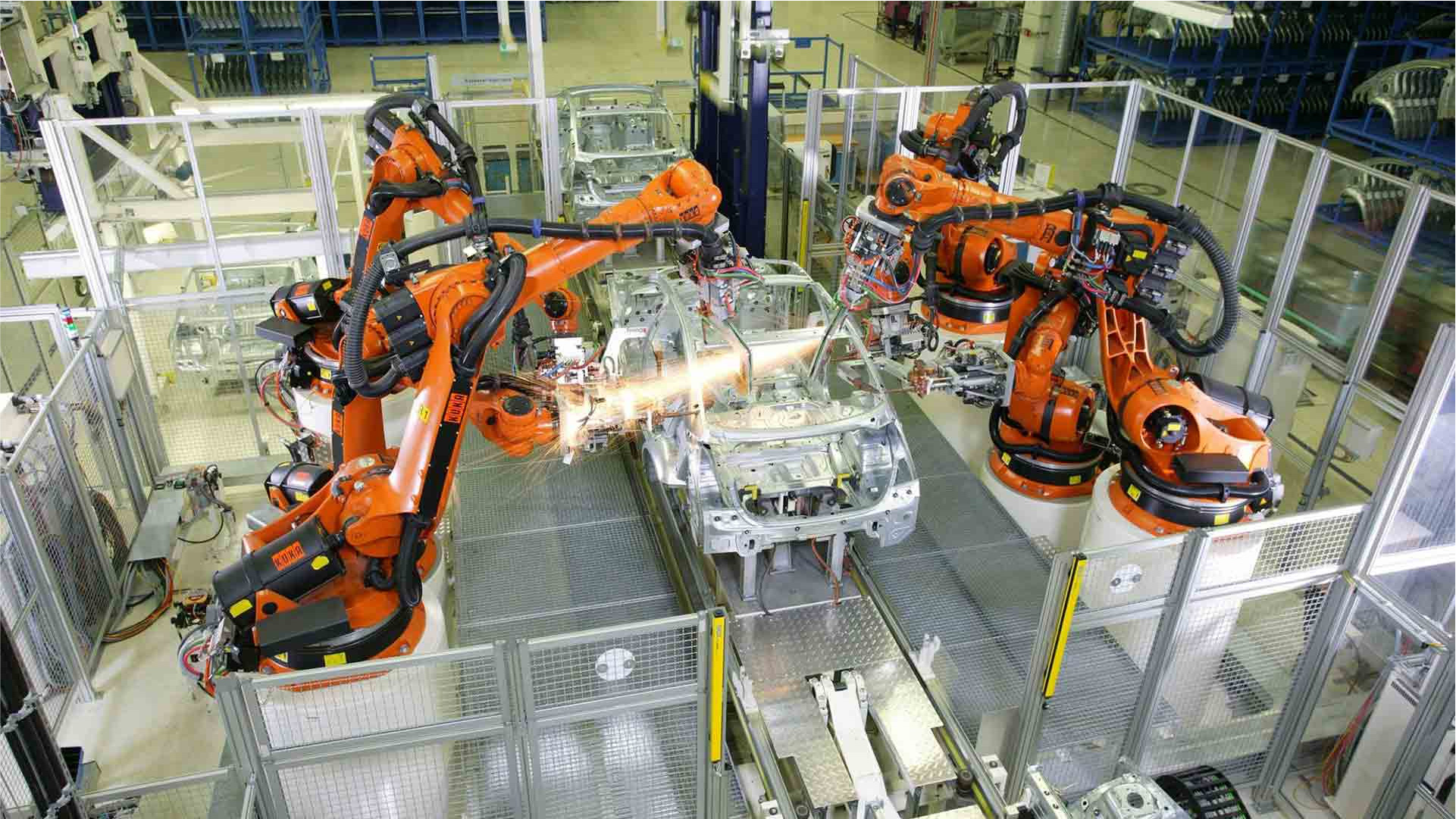

Today more and more industries are replacing their fluid power actuators with more efficient and cleaner electric ones. Why? Well, tasks that were once limited to hydraulic and pneumatic cylinders, such as pressing, holding and lifting are now being carried out by electric actuators. Lower life-cycle costs, higher speed, accuracy and flexibility, are some of the contributing factors when it comes to increased production.

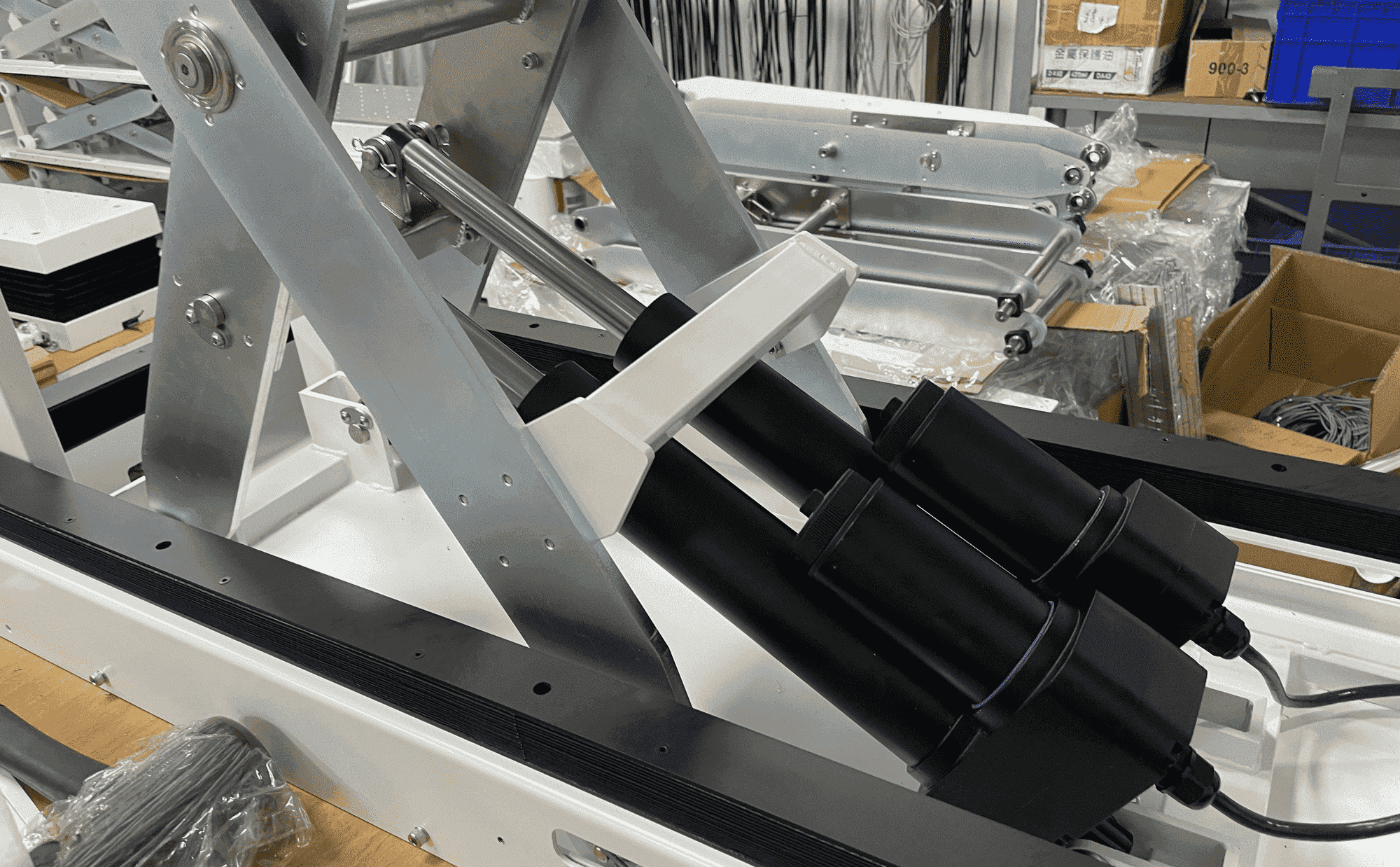

Econ Robot INC, established in 2000 in Taiwan, has always been committed to developing automation components based on green energy and environmental protection. Using electric actuators has helped the company achieve its green goals, increase productivity, and reduce life-cycle costs. Recently, the company has realized a series of Autonomous Guided Vehicles (AGV) to equip a flexible assembly line of scooters. These devices are used to move the scooters across the different assembly stations, lifting it at the right height for the operators.

“Initially faced with the challenges of switching from hydraulic actuators to electric actuators, we needed to source a product that could deliver on our environmental promises, improve operational efficiency, but still have the necessary features to increase productivity, says Wesley Ho, vice president of ECON. For this reason, we chose Ewellix's CAHB-22E linear actuators”.

Fast and smooth movement, easy and fast integration

Why does Ewellix’s CAHB-22E actuators satisfy the needs of Econ Robot INC?

Wesley stated that “electromechanical systems can be as high as 85% more energy efficient, while the normal efficiency of hydraulic systems is about 30%, together with the advantage of no fluid leakage, which can be messy, dangerous and pollutive, it reduces operational costs as well as helping towards a better environment”.

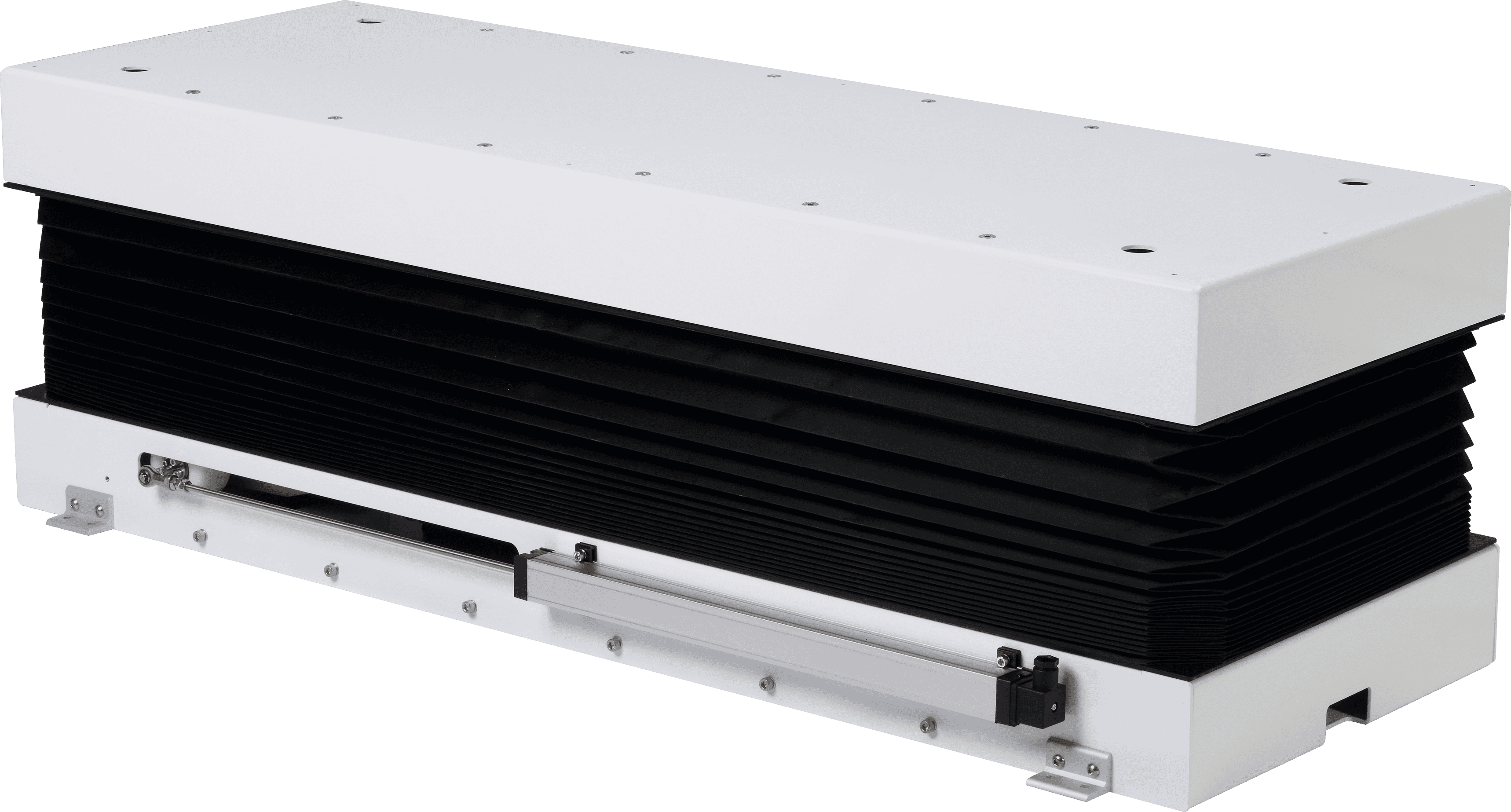

The CAHB-22E linear actuator can achieve increased productivity with its fast and smooth movement while still delivering a push-and-pull load of up to 10,000 N.

“Once we replaced hydraulic cylinders with electromechanical systems, our orders increased as many of our customers needed low-noise equipment and could operate in a clean environment. Creating an oil-free environment and simplifying the layout has also helped with machine design; electromechanical actuators require only 10% of the installation time of hydraulic cylinders. Now we only need to install actuators and set the program. No need to install fluid tubes or connect hoses or accessories," said Wesley.

Ewellix electromechanical CAHB linear actuators are engineered to operate in severe environments and at temperatures from -40 to +85 °C protection class.

All CAHB linear actuators from Ewellix are virtually maintenance-free, self-locking up to two times the rated load and protection class up to IP69K/66M.

About Econ Robot INC

With its headquarters based in Zhubei City, Hsinchu County, Taiwan, one of the fastest-growing towns in Taiwan, it was initially set up as an agent for several Japanese industrial manipulators. In 2004 it established its automatic logistics department, and in 2012, it merged with its automation equipment division. In 2015, AGV solution packages, called K-kit and Linear shaft motor modules, with ECON owed brands, were established. Today ECON is responsible for developing and manufacturing electric actuators, electric cylinders, electric grippers, single robots, desktop robots, automated guided vehicles, and other automatic transmission components.

Our products are used in thousands of industrial applications

Read more

Need more

information?

Ask our experts.