Ewellix's solid and comprehensive product knowledge combined with their engineering expertise is transforming customer needs into tailor-made solutions.

Focusing on client-specific requests our engineers support customers in developing and putting in place cost-effective custom actuators for high performances for niche markets and high volume applications.

Our strong understanding of linear and actuation technologies enables us to create new solutions which are based on proven processes and several basic elements.

Please contact our Ewellix sales team for more information on custom actuators for high performances and how we can help you.

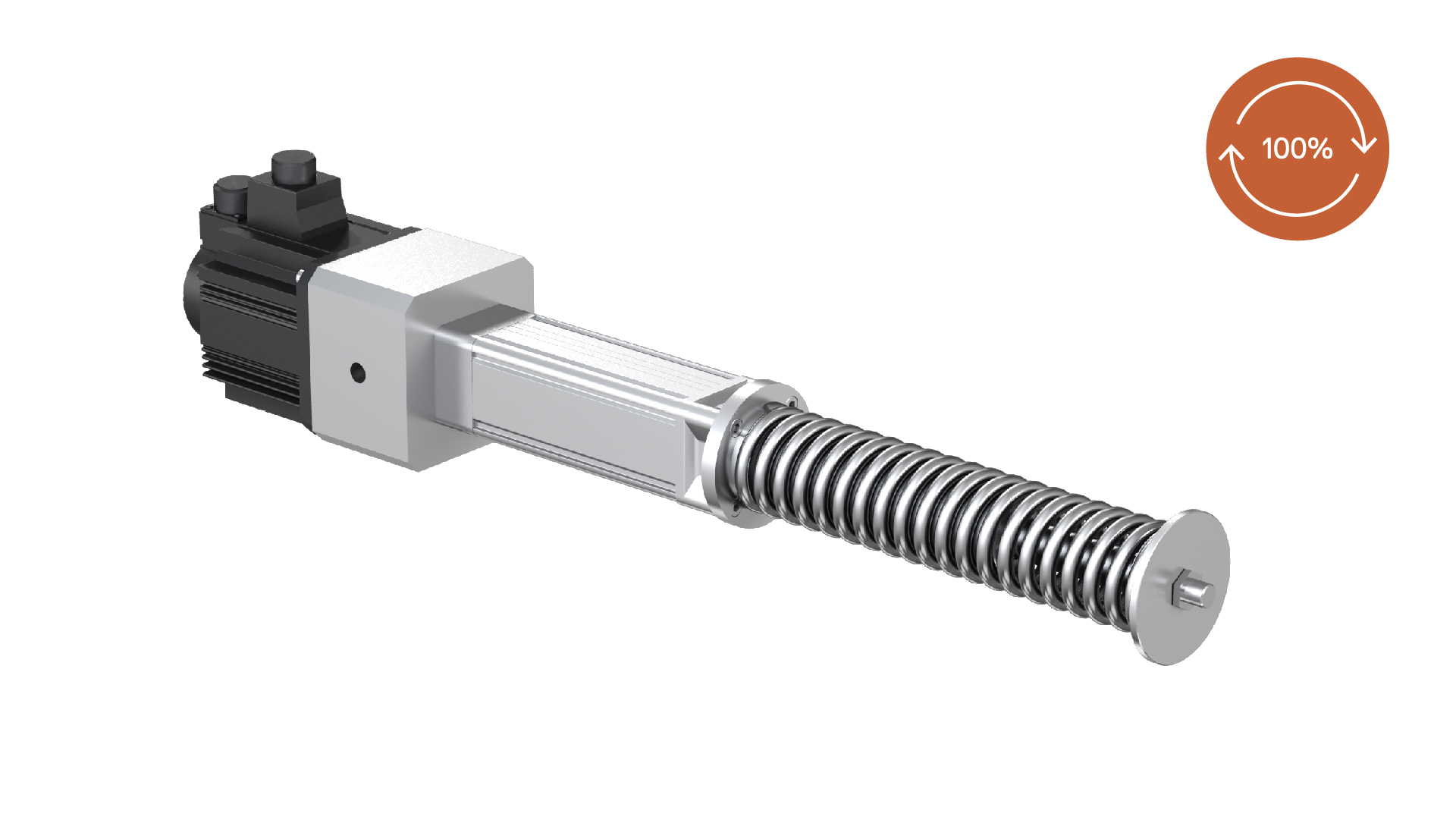

CASM with spring around the push tube

Ewellix has equipped the thrust tube with a rotating spring to relieve the load on the motor and spindle inside the cylinder. This spring carries a large part of the constant load. The motor and spindle are primarily used to accelerate and decelerate the moving load. This increases the service life of the cylinder and enables the use of a smaller motor.

CASM made of stainless steel

Ewellix has developed a CASM special version made of stainless steel suitable for direct contact with foodstuffs in accordance with EHEDG guidelines (Doc. 8). This cylinder has a rounded and smooth surface preventing food residues and bacteria from accumulating. It is made of stainless steel, resistant to the usual chemicals and solvents used in the food industry and can be cleaned at high pressure.

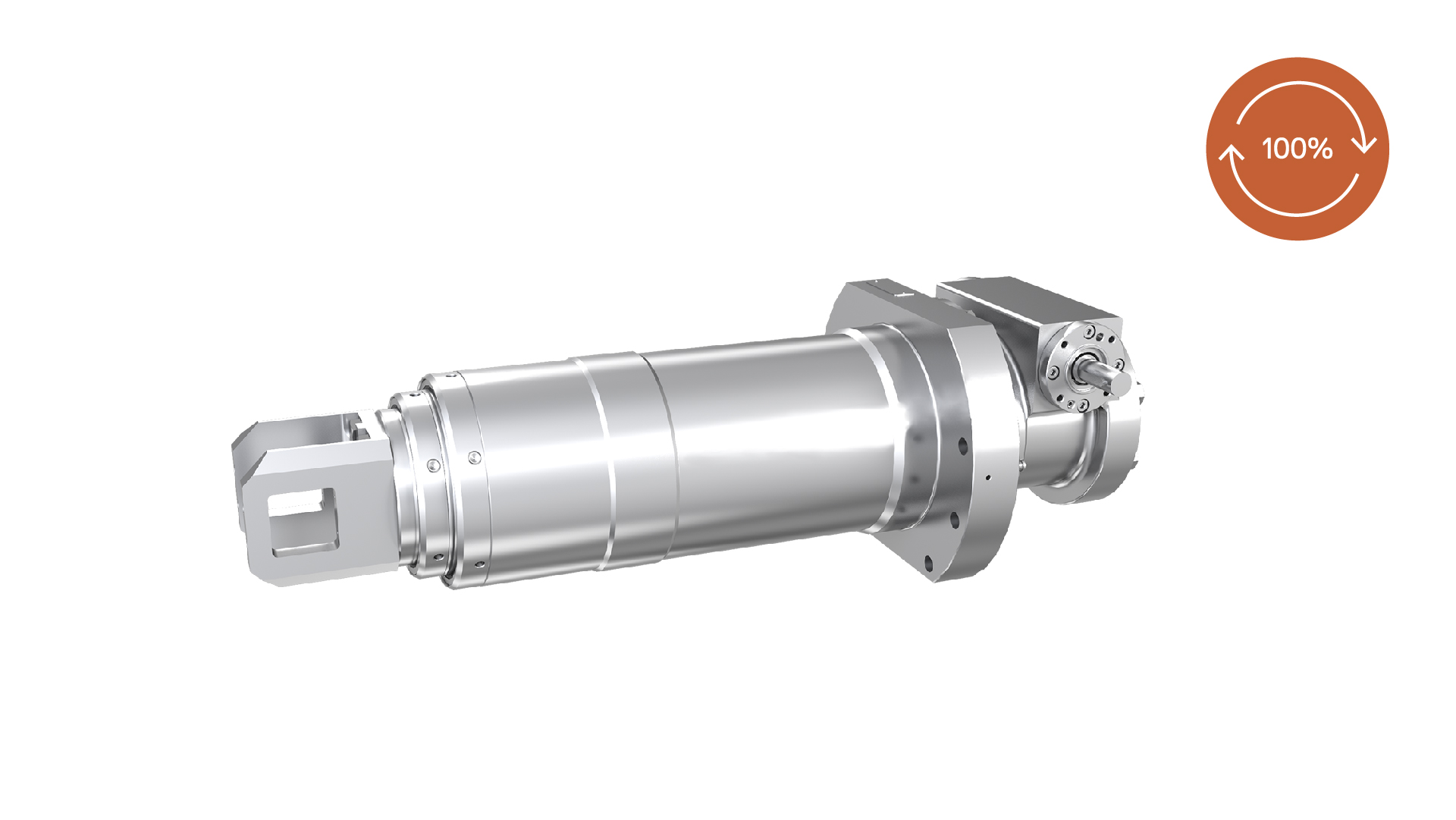

Electric cylinder for height adjustment on working platform

The task was to provide an electromechanical solution with a stroke of 300 mm, a maximum load capacity of 70 kN and a maximum weight of 50 kg. The solution we came up with was an actuator with a roller screw drive, planetary gear and a highly compact servo motor.

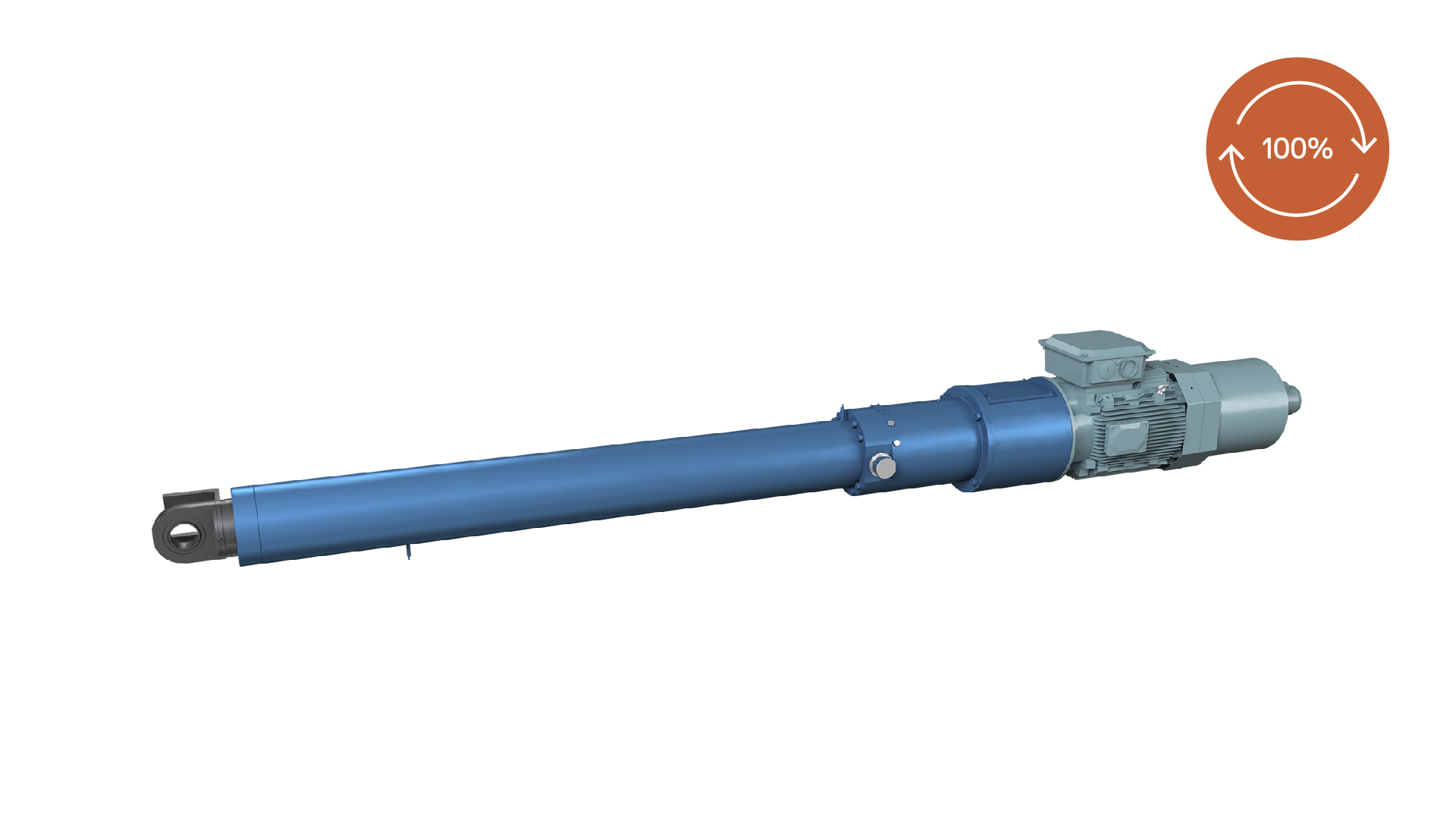

Cylinder with very long stroke length

At the sluice gates of a Swedish hydroelectric power station, the hydraulic cylinders needed to be replaced in order to avoid future oil leaks and optimise operating time. The solution was to develop a cylinder with a long stroke (3,100 mm) and high load capacity that would function reliably even under extreme conditions.

Telescopic electric cylinder

Ewellix has developed telescopic drives with ball screws especially developed for the steel industry, which can be used to adjust the mould and bloom size during continuous casting. The telescopic design offers a longer stroke with the same installation length, giving the user more choice in casting.

Extreme power SRSA electric cylinder

Ewellix has developed a tailor-made SRSA cylinder with top performance to replace the existing hydraulic system for heavy duty applications in the steel industry. With its asynchronous motor (30 kW), this actuator can deploy a movement force of up to 110 kN and, when fully extended has a total weight of 1.3 tonnes and a length of 6 metres.

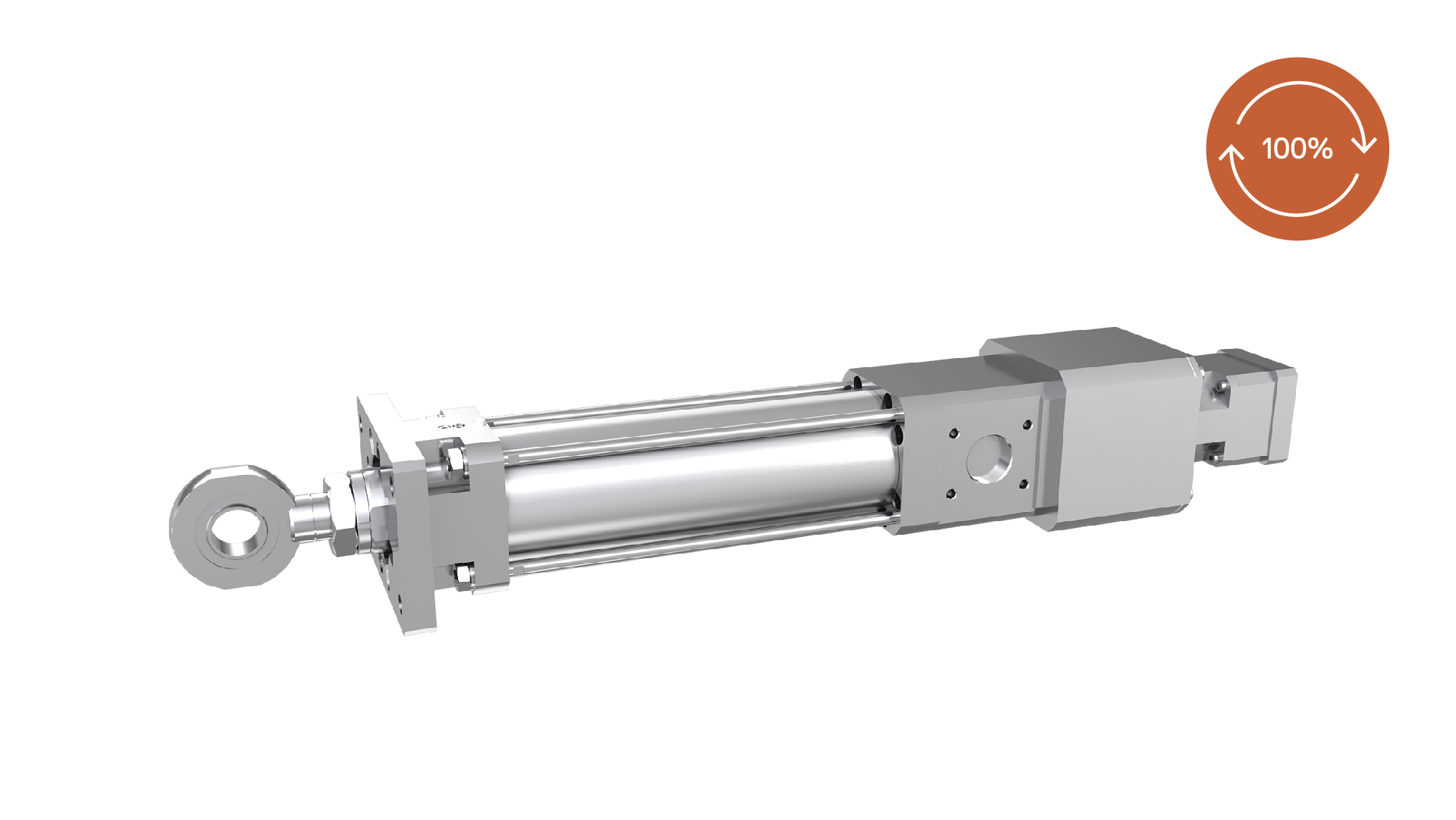

LEMC with recirculating roller screw

A testbed for analysing material resistance and distortion should be equipped with a system that provides rigidity and high motion resolution even at minor linear displacements per motor revolution. As a solution, Ewellix showcased a combination of a preloaded roller screw drive with a roller recirculation system and a planetary gear, eliminating the problem of displacements in the micrometer range.

Cylinder for parallel running

A solution was required for difficult environments with high accuracy and stability and a load capacity of up to 160 kN. A system was supplied in parallel with a custom gearbox, robust seal, <a href="https://www.ewellix.com/en/products/ball-and-roller-screws/roller-screws" title="roller screws">roller screws</a>, servo motor and a redundant brake system.Need more

information?

Ask our experts.