Ewellix 7th axis solutions for collaborative and industrial robots

Ewellix 7th axis solutions for collaborative and industrial robots

Ewellix 7th axis solutions for collaborative and industrial robots

Ewellix provides effective solutions to complete vertical and horizontal movement in a smart way, providing plug-and-play additional linear axis to the robot.

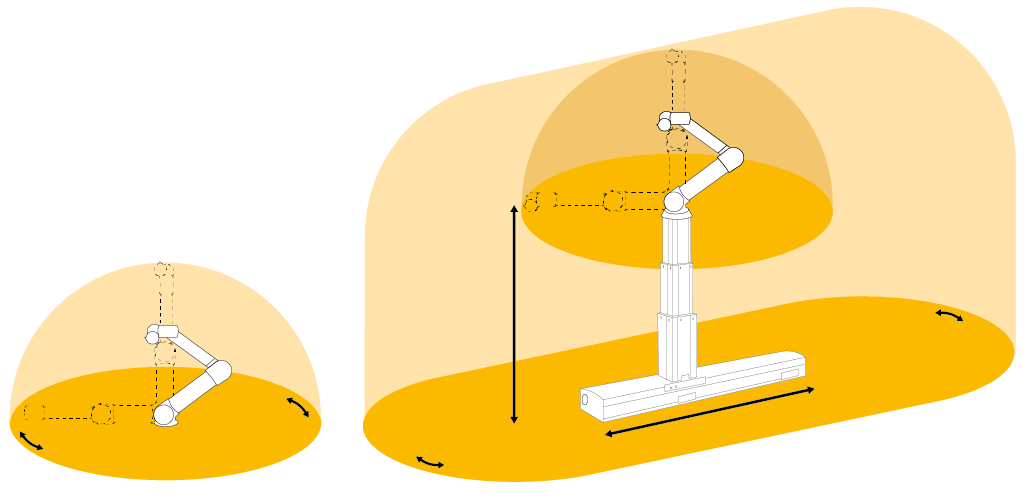

Robot operating range extension

Increase the robot’s working range with vertical and horizontal movements.

Cost optimization

Effective solutions to fully automate operations for increased productivity and lower total cost of ownership.

High repeatability

Ability to perform repetitive tasks usually performed manually.

Sensors and edge software extend the robot's operating range

- Additional linear axes increase the robot reach by up to 7 times

Easy to install plug-and-play systems

- Ready to use compatible package with leading robot brands

- Fully integrated into robot environment

High reliability

- Robust design for industrial use with high stiffness

- High positioning precision and stability

- Thousands of units working on the field in multiple applications

High safety

- Anti-pinching function

- Emergency stop connection to robot up to safe torque off PLe, Cat.4

Easy maintenance

- LIFTKIT virtually maintenance free

- SLIDEKIT easy access to outside lubrication port

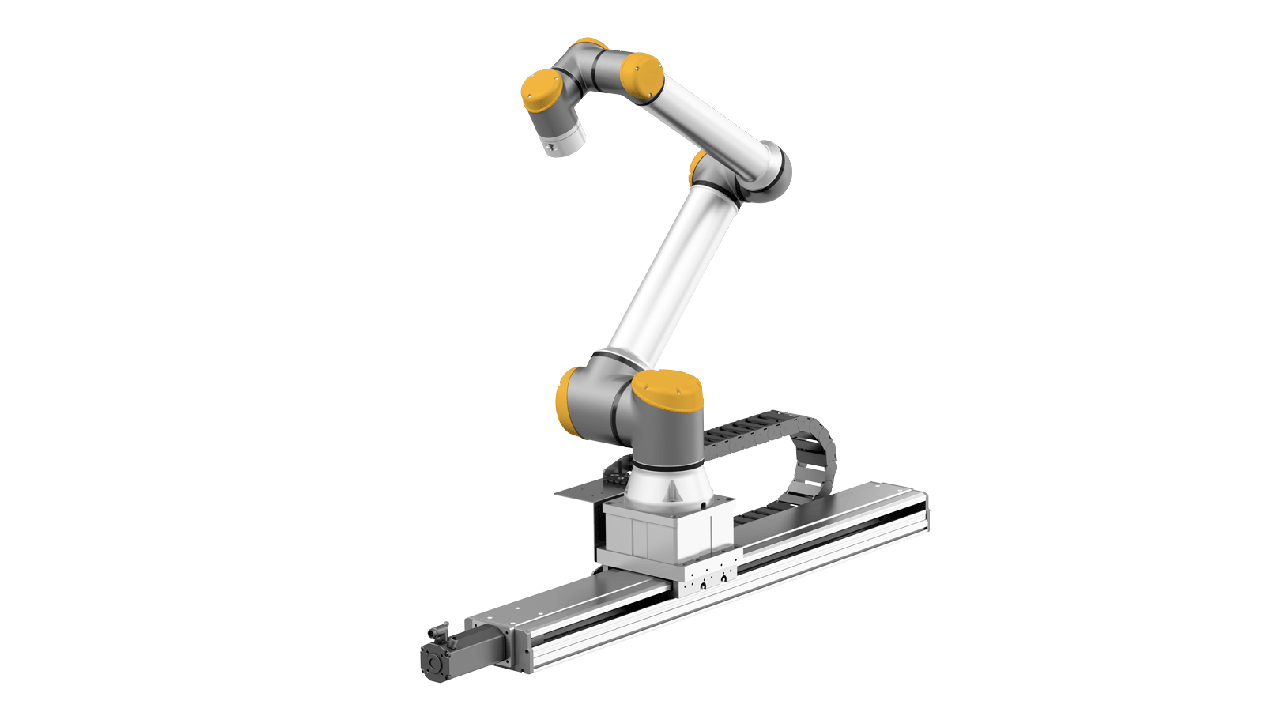

The SLIDEKIT enables fast movement along the horizontal axis and precise positioning to increase productivity and save costs. The stability and reactivity of the system guarantee a high level of output quality. The SLIDEKIT comes with a fully integrated software and is plug-and-play.

ㅤ

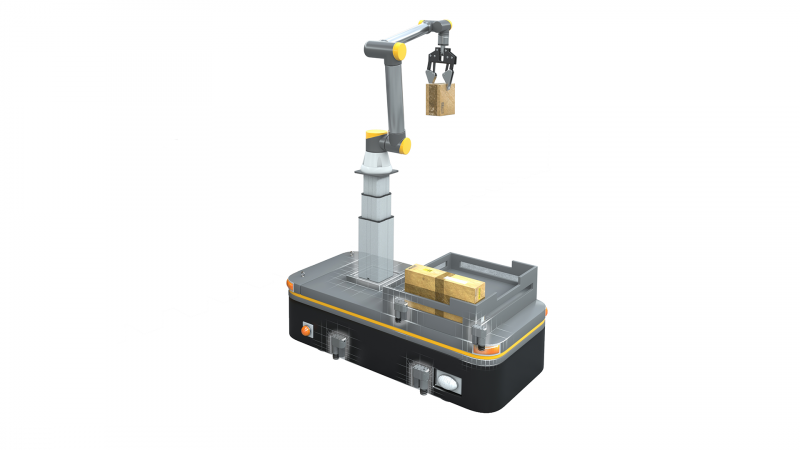

The LIFTKIT is an effective solution extending the reach of the robot along the vertical axis to save cost and increase productivity.

Thanks to its precise movement the LIFTKIT raises or lowers the robot always to the optimal position. It comes with a fully integrated software and is plug-and-play.

Explore your benefits

Plug-and-play

Easy installation with fully integrated software

Safety

- Emergency stop connected to robot up to Safe Torque Off PLe, Cat.4

- Anti-pinching function

Safety

- Emergency stop connection to robot up to Safe Torque Off PLe, Cat.4

- Anti-pinching function

Safety

- Emergency stop connected to robot up to Safe Torque Off PLe, Cat.4

- Anti-pinching function

No cable stress

Large energy chain compliant with robot manufacturers’ specifications

Operating range extension

SLIDEKIT stroke up to 3 000 mm movement of horizontal axis

Easy maintenance

SLIDEKIT easy access to outside lubrication port

Easy maintenance

LIFTKIT virtually maintenance free

Extension

LIFTKIT stroke up to 1 400 mm movement of vertical axis

Listen to what our customers say

Do you have any questions?

Contact our experts.

Fill in the form with your contact and briefly explain your request. We will contact you soon.