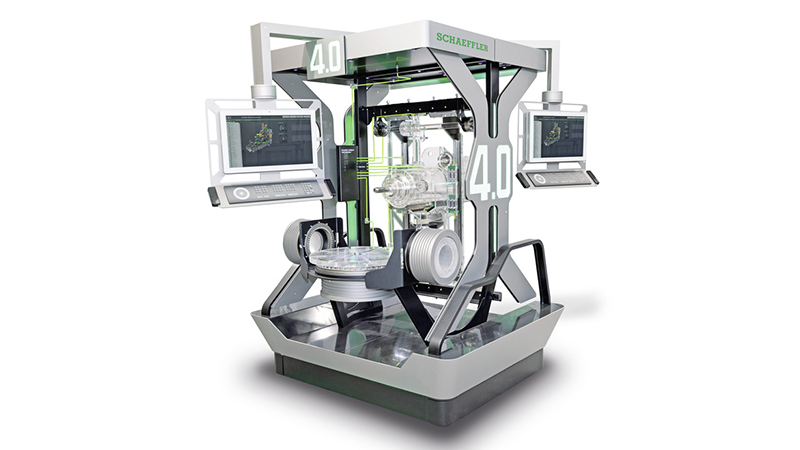

Schaeffler has been proving its role as a market-leading system supplier in the machine tool industry for decades with innovative solutions for machining and forming operations. It is not just the rolling bearing component that is essential for the success of our products – it is the integration of important functions such as driving, bearing and guidance, measuring and monitoring, sealing and lubrication in an optimally coordinated system solution.

This is why today we are not only a supplier of highly specialized rolling bearings, but also of direct drives and integrated measuring systems. We develop our products based on a deep understanding of the system, starting with the rolling contact, magnetic flux, tribology etc. through to the complex interactions between the rolling bearing and linear guide, motor, gearbox and housing in the machine.

Industry Challenges

More than ever before, our components and subsystems need to be tailored to the machine tool type and the specific stress resulting from the machining task at hand. We achieve this with detailed analyses, simulations and the expertise we have built up over decades in the machine tool industry. With innovative new developments, we help our customers to overcome technical limits over and over again.

“At Schaeffler, our customers are always at the center of everything we do. Our goal is to thoroughly understand applications and build our portfolio based on that understanding. Over the decades, this has led to the creation of a modular system of solutions that delivers added value to our customers and provides the optimal solution for every application. Our global team of experts is equipped with the knowledge and resources necessary to support our customers and – where needed – to continually develop our modular system of solutions.”

Ralf Moseberg, Senior Vice President Industrial Automation

Products

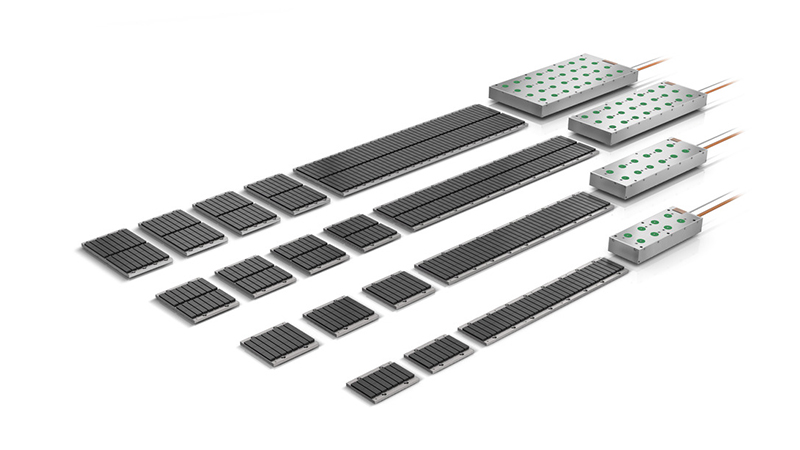

Whatever the application – whether components for main axes, rotary and swivel axes, or spindle components – our products and systems deliver the optimal solution for your axes.

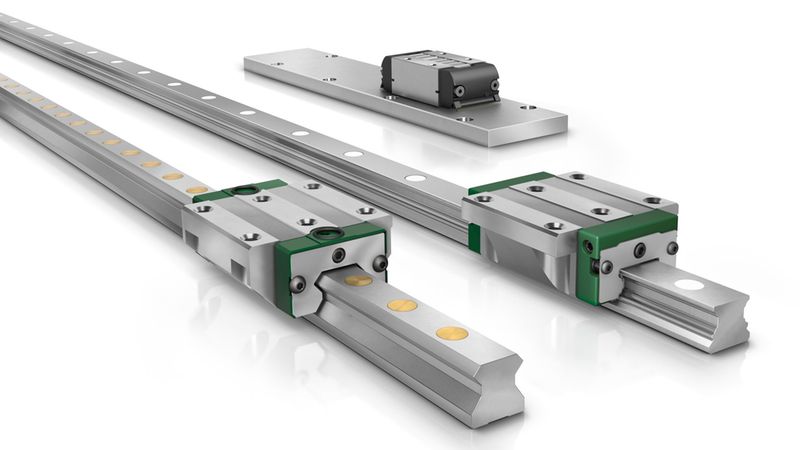

Components for main axes (X, Y, Z)

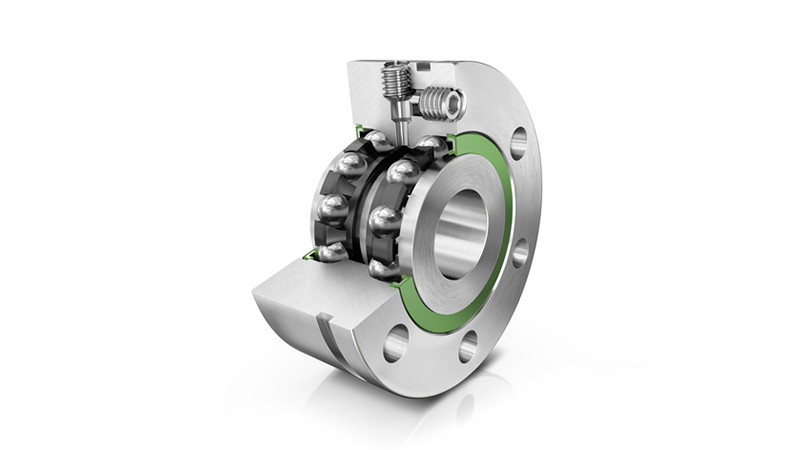

Components for rotary and swivel axes

Our rotary axis bearings differ primarily in terms of speed range, load capacity, and tilting rigidity. All YRTC, YRTS, and ZKLF rotary axis bearings share the same external geometry, making them interchangeable without the need for redesign. Additionally, these rotary axis bearings can be combined as needed with our torque motor series. This makes it possible to develop production-ready rotary axes with the desired performance and precision for virtually all machining processes in a short time.

Spindle components

Schaeffler offers a comprehensive and precisely tiered portfolio of spindle bearings, along with full engineering services throughout spindle development. By using various high-performance materials for bearing rings, rolling elements, and cages, the bearings can also be perfectly adapted to extremely demanding applications.

Publications

Schaeffler bearing solutions offer precisely the right precision, rigidity, service life, and dynamics for your application. Our broad portfolio of ready-to-install components, mechatronic solutions, and integrated additional functions enables you to create extremely compact, energy-efficient, and robust machine and automation axes. You can find comprehensive information and a wide range of materials about our solutions in the Media Library.